| Bucket Capacity: 1m³ |

| Working Hours: ≥530hours |

| Year: 2024 |

| Brand: Komatsu |

| Shipping: Bulk cargo / Container/Flat Rack |

Japan Komatsu PC220-8 Crawler Excavator, Low Price Komatsu 22Tonne Excavator PC220 Crawler Excavator Original

Why Choose Us

We have a strong mechanical team to ensure that all machines are well maintained, of high quality, and

100% original.

Spare parts are available, the most suitable for your machine.

We offer almost all types of second-hand construction machinery in good condition and at low prices.

Product Introduction

| Bucket Capacity: 1m³ |

| Working Hours: ≥530hours |

| Year: 2024 |

| Brand: Komatsu |

| Shipping: Bulk cargo / Container/Flat Rack |

Comprehensive description of Komatsu PC220-8 excavator:

1. Basic parameters and performance

Power system

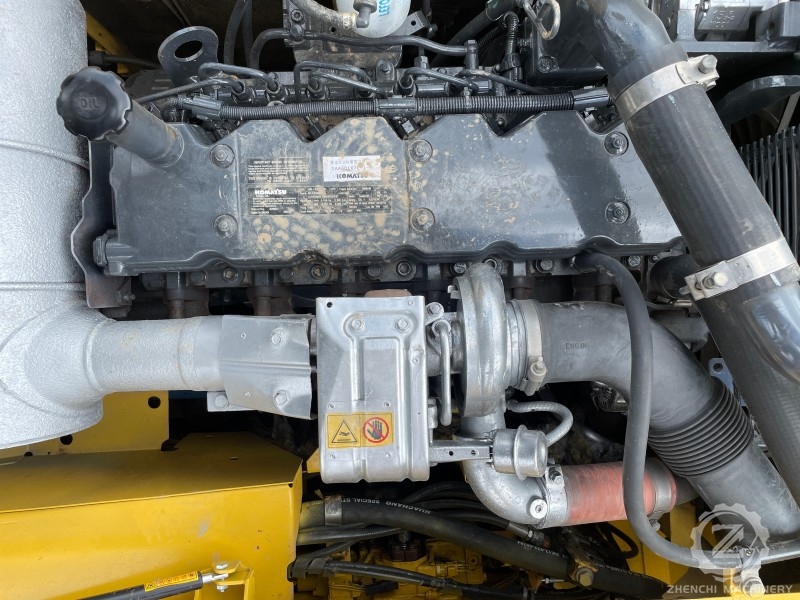

Engine model: Komatsu SAA6D107E-1 high-pressure common rail electronic fuel injection engine, 6-cylinder inline design, turbocharged + aftercooling, displacement 6.69 L, rated power 125 kW (170 horsepower) / 2000 rpm, meeting EPA Tier3 and EUIIIA emission standards.

Fuel tank capacity: 400 L, supporting long-term continuous operation.

Complete machine configuration

Working weight: 22.3-23.6 tons (different configurations), standard version is 23,100 kg.

Bucket capacity: standard 1.0 m³, some versions can be optional 0.72-1.45 m³, to meet the diverse needs of earthwork, mining, etc.

Travel speed: three-speed transmission, up to 5.5 km/h, gradeability 70% (about 35°), ground pressure 50.0-51.2 kPa, strong terrain adaptability.

Operation capability

Digging depth/height: maximum digging depth 6.92 meters, maximum digging height 10 meters, maximum vertical digging depth 6.01 meters, suitable for deep foundation pits and complex terrain operations.

Digging force: maximum digging force of bucket 172 kN, digging force of bucket arm 129 kN, traction force 202 kN, strong power output.

2. Core technology highlights

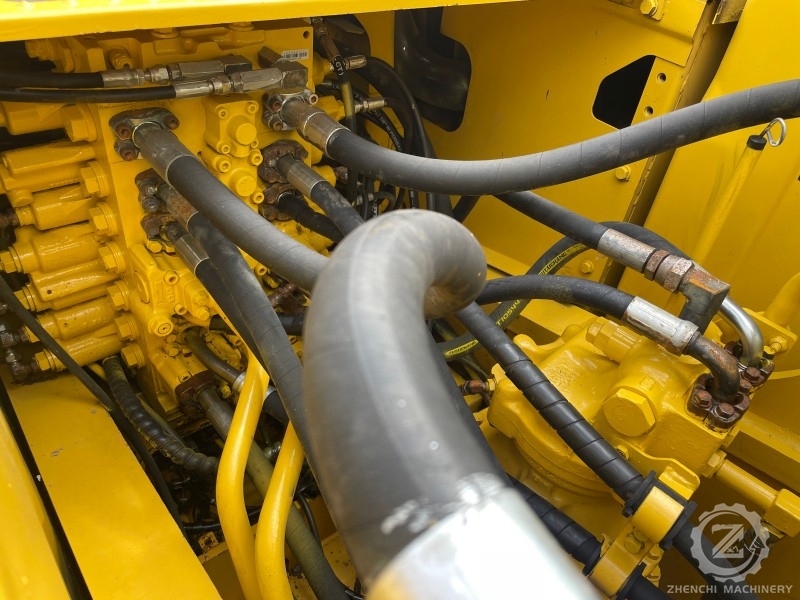

Hydraulic system

Adopting closed-center load sensing system (CLSS), the maximum flow of the main pump is 439 L/min, the working pressure is 37.3 MPa, and the swing circuit is 28.9 MPa, achieving efficient movement and precise control.

The axial piston motor drives walking (with parking brake) and swing (with holding valve), with high movement coordination, especially suitable for high-frequency operations such as loading and dumping.

Structure and durability

Heat dissipation optimization: parallel cooling system design improves the heat dissipation efficiency of the engine and hydraulic system.

High-strength structure: The boom and dipper are made of reinforced steel, the chassis track width is 600 mm, and the ground length is 3460 mm, which enhances stability under complex working conditions.

Intelligent control and maintenance

Standard KOMTRAX remote monitoring system, real-time feedback of machine status and operation data.

Easy maintenance: oil-water separation fuel pre-filter, quick maintenance point design (such as air conditioning filter, oil filter) reduce the difficulty of maintenance.

3. Operation and configuration expansion

Cab design

High damping shock-absorbing seat with low noise (about 67 decibels) cab, standard air conditioning, optional rearview camera to improve safety.

Multi-functional adaptability

Supports accessories such as breaker and ripper, but attention should be paid to the oil temperature control of the hydraulic system under high-intensity crushing operations (intermittent use is recommended).

Optional extended arm configuration to expand the adaptability of deep foundation pit excavation or high-rise demolition scenes.

related products

Leave Us A Message