| Bucket Capacity: 1m³ |

| Working Hours: ≥1900hours |

| Year: 2021 |

| Brand: Komatsu |

| Shipping: Bulk cargo / Container/Flat Rack |

China Supplier Offers Low Price Used Komatsu PC220-7 Komatsu Pc220 With Core Engine Component

Why Choose Us

We have a strong mechanical team to ensure that all machines are well maintained, of high quality, and

100% original.

Spare parts are available, the most suitable for your machine.

We offer almost all types of second-hand construction machinery in good condition and at low prices.

Product Introduction

| Bucket Capacity: 1m³ |

| Working Hours: ≥1900hours |

| Year: 2021 |

| Brand: Komatsu |

| Shipping: Bulk cargo / Container/Flat Rack |

Komatsu PC220-7 excavator is a medium-sized crawler hydraulic excavator produced by Komatsu, suitable for earthwork, building demolition, road construction and other scenarios. The following is a comprehensive description:

1. Basic parameters

Power and weight

Engine model: Komatsu SAA6D102E-2, 4-stroke water-cooled direct injection turbocharged engine, rated power 125 kW (about 170 horsepower), speed 2000 rpm, displacement 5.883 L.

Working weight of the whole machine: 22.3-22.9 tons (22840-22900 kg), slightly different due to different configurations.

Fuel tank capacity: 400 L, supports long-term continuous operation.

Operation capacity

Bucket capacity: standard configuration 1.0 m³

Digging depth: maximum digging depth 5.825-6.92 meters, vertical digging depth 4.75-6.01 meters, to meet the needs of different working conditions.

Digging force: Maximum digging force of bucket is 172 kN, digging force of bucket arm is 129 kN, and traction force is 174-202 kN.

Travel speed: Three-speed transmission, maximum 5.5 km/h, climbing ability 70% (about 35 degrees).

2. Technical highlights

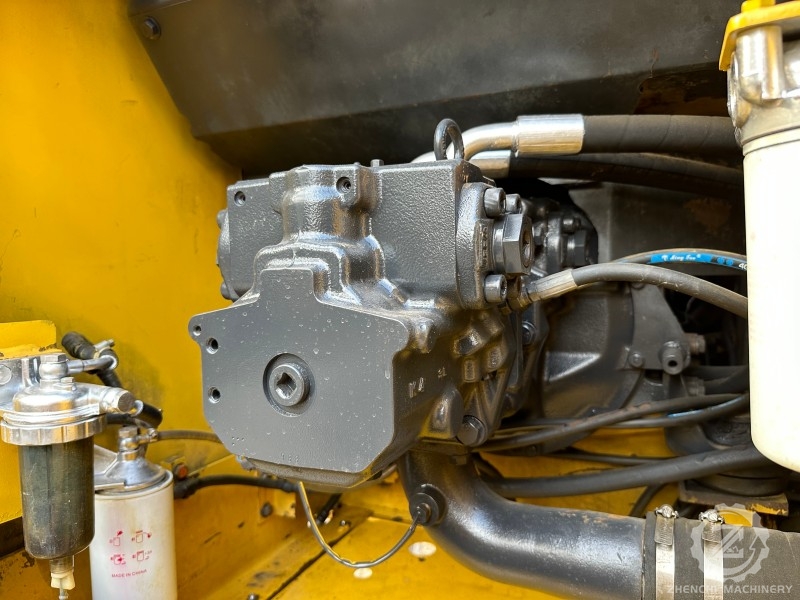

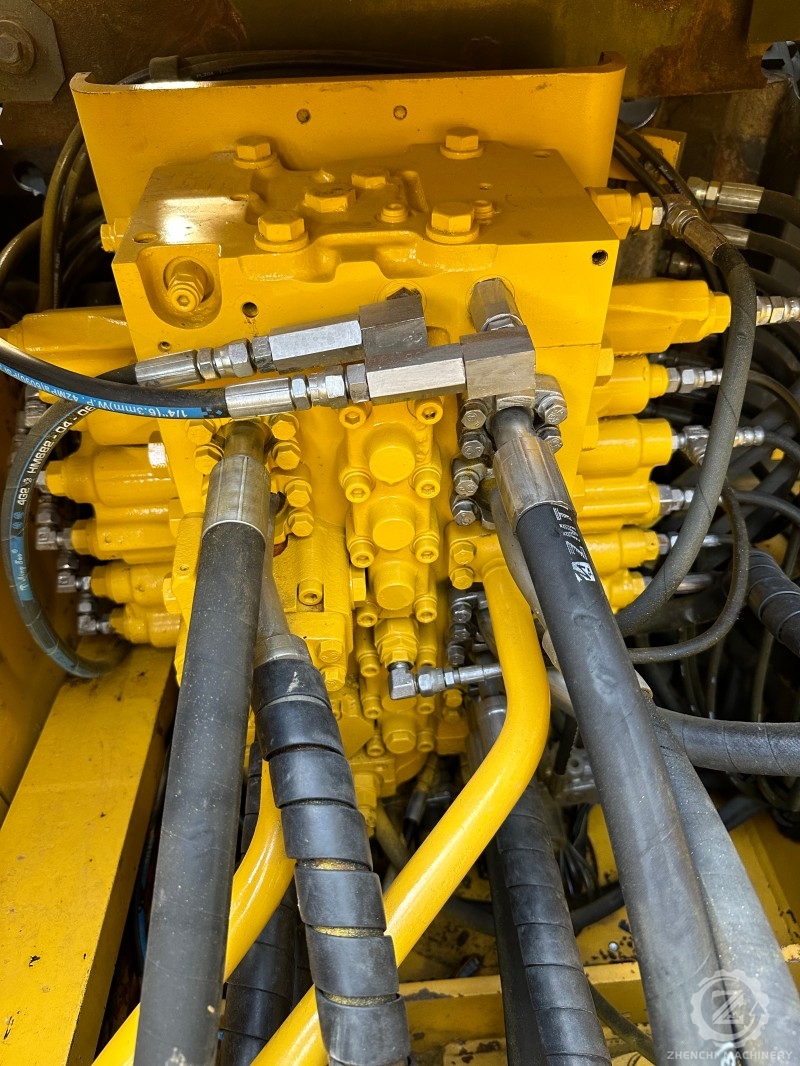

Hydraulic system

Adopts closed-center load sensing hydraulic system (CLSS), the maximum flow of main pump is 439 L/min, working pressure is 37.3 MPa, and the swing circuit is 28.4 MPa, providing efficient and stable operating performance.

Equipped with axial piston hydraulic motor, the walking and swinging movements are precise, suitable for high-frequency loading, soil throwing and other operations.

Power and fuel efficiency

The engine adopts turbocharging and intercooling technology, combined with electronically controlled fuel injection system, to optimize combustion efficiency and reduce fuel consumption.

User feedback shows that the fuel economy of this model under standard working conditions is better than similar competing products.

Structure and durability

The chassis adopts a box-section structure and a sealed track design, with a track shoe width of 600 mm and a ground pressure of 50 kPa, which enhances the passability and stability of complex terrain.

Key components such as booms and dipper cylinders are made of high-strength steel. The long-term wear parts are mainly chains and hydraulic pipes, and the maintenance cycle is long.

III. Operation and configuration

Driving and maintenance

The cab is compactly designed, with air conditioning and low noise system (about 67 decibels) as standard. Some models can be equipped with optional rearview cameras to improve safety.

The hydraulic oil tank capacity is 143 L, the engine oil replacement volume is 24 L, the maintenance points are clearly marked, and quick maintenance is supported.

Multi-functional adaptability

Supports accessories such as breaker hammers and ripper, but the hydraulic system is sensitive to the load of long-term crushing operations, and attention should be paid to oil temperature control (high temperature can reach 90°C).

Optional different bucket capacities (0.72-1.3 m³) and extended arm configurations to expand adaptability to scenarios such as deep foundation pit excavation

related products

Leave Us A Message