| Working Hours: ≥400hours |

| Year: 2024 |

| Brand: Other Construction Machinery |

| Shipping: Bulk cargo / Container/Flat Rack |

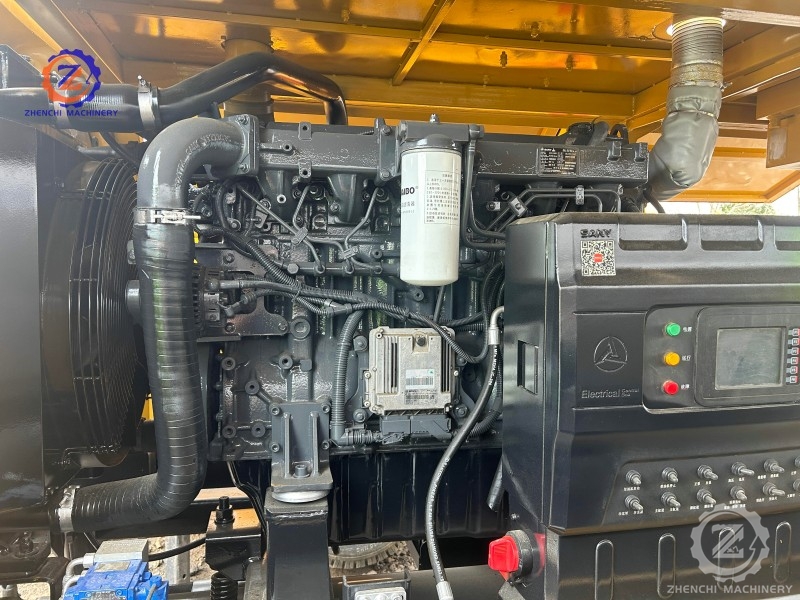

Used Sany Trailer Mounted Concrete Pump Hbt80 diesel Stationary Concrete Pump for Sale

Why Choose Us

We have a strong mechanical team to ensure that all machines are well maintained, of high quality, and

100% original.

Spare parts are available, the most suitable for your machine.

We offer almost all types of second-hand construction machinery in good condition and at low prices.

Product Introduction

| Working Hours: ≥400hours |

| Year: 2024 |

| Brand: Other Construction Machinery |

| Shipping: Bulk cargo / Container/Flat Rack |

Comprehensive description of Sany HBT80C trailer pump:

1. Basic parameters and performance

Power type and core parameters

Electric trailer pump: mainstream models such as HBT80C-1816ⅢA, motor power 132kW, maximum theoretical displacement 85m³/h, delivery pressure 16MPa (10/16MPa in low pressure/high pressure mode). Some electric models have a main drive power of up to 181kW, and a maximum delivery distance of 100 meters vertically and 400 meters horizontally.

Diesel trailer pump: For example, HBT80C-2122Ⅲ, using dual motors (2×110kW), maximum delivery pressure 22MPa, displacement 85m³/h, suitable for projects with higher pressure requirements.

Delivery capacity and adaptability

Theoretical delivery volume: low pressure mode can reach 85m³/h, high pressure mode drops to 55m³/h (depending on the specific model).

Aggregate adaptability: Maximum aggregate particle size 40mm (Φ125mm pipe diameter) or 50mm (Φ150mm pipe diameter), concrete slump support 100-230mm.

Pumping distance record: Sany trailer pump has set a record of vertical pumping 392 meters (Hong Kong International Financial Center) and horizontal pumping over a kilometer (Qingdao Bay Bridge).

Structural design

Hydraulic system: Full hydraulic reversing open system, low oil temperature, small reversing impact, high hydraulic oil cleanliness.

Wear-resistant technology: S-tube valve system is adopted, with good sealing and convenient replacement of wearing parts; automatic return technology of concrete piston simplifies maintenance.

Oil tank and drive: Hydraulic oil tank capacity is 600L, and the diameter × stroke of the delivery cylinder is Φ200×1800mm26.

2. Core technical features

Intelligent control system

Equipped with the first SYMC and SYLD intelligent control systems in China, it supports color graphics to dynamically display operating parameters, fault self-diagnosis and multiple automatic protection.

Electro-hydraulic proportional displacement is steplessly adjustable to meet the needs of different working conditions.

Energy saving and stability

Electric models are significantly more energy-efficient than diesel drives, and support remote control and automatic lubrication functions.

Adopting international brand hydraulic/electric components (such as Rexroth hydraulic parts, Siemens electronic control system), it has high reliability.

Safety and convenience

High and low pressure automatic switching patented technology, quickly solve the pipe blockage problem through button switch operation, no hydraulic oil leakage.

Main cylinder waterproof sealing technology prevents hydraulic oil emulsification and extends equipment life.

3. Application scenarios and advantages

Applicable projects: large buildings (such as super high-rise buildings), bridges and tunnels, ports, etc. Typical cases include Shenzhen Ping An Financial Center (pumping height exceeds 1,000 meters) and Changsha Guojin Center (452 meters).

Advantages:

Efficiency: The dual-circuit hydraulic system operates synchronously to improve pumping efficiency.

Flexibility: The trailer speed is up to 40km/h, which is convenient for site transfer.

Environmental protection: Electric models have zero emissions, and diesel models meet European and American low emission standards.

IV. Notes

Model differences: The HBT80C series includes multiple sub-models (such as 1816ⅢA, 2122Ⅲ, 1813Ⅲ, etc.), and the parameter configurations vary greatly. The actual sales information shall prevail.

Maintenance requirements: The hydraulic oil, lubrication system and pump pipe wear must be checked regularly to avoid the risk of pipe blockage.

related products

Leave Us A Message